Atomization is the breakup of a bulk liquid into a spray of small droplets. A multitude of atomizer designs are used in everyday life and throughout industry to distribute liquid coatings across surfaces, increase liquid surface area for evaporation or combustion, or create particles and powders. The magnitude of energy spent on liquid atomization is immense, and a variety of physical mechanisms are employed to accomplish breakup, each with unique advantages and limitations. The assistance of a pressurized gas is often used in applications desiring small droplets at system pressures under 100 psig, especially when spraying liquids with high viscosity or solids content.

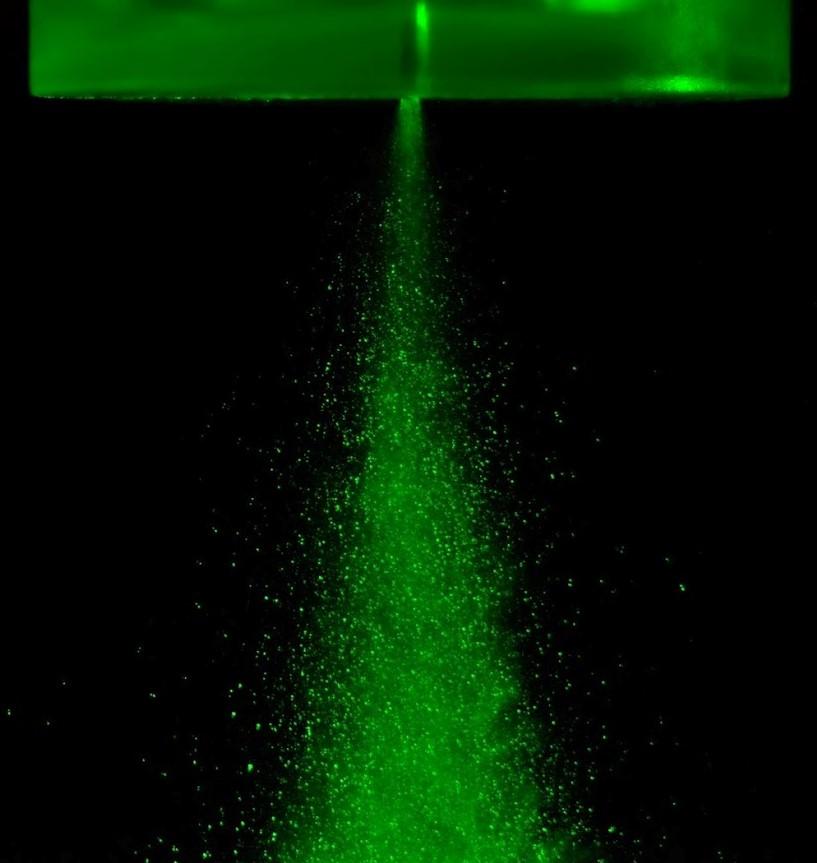

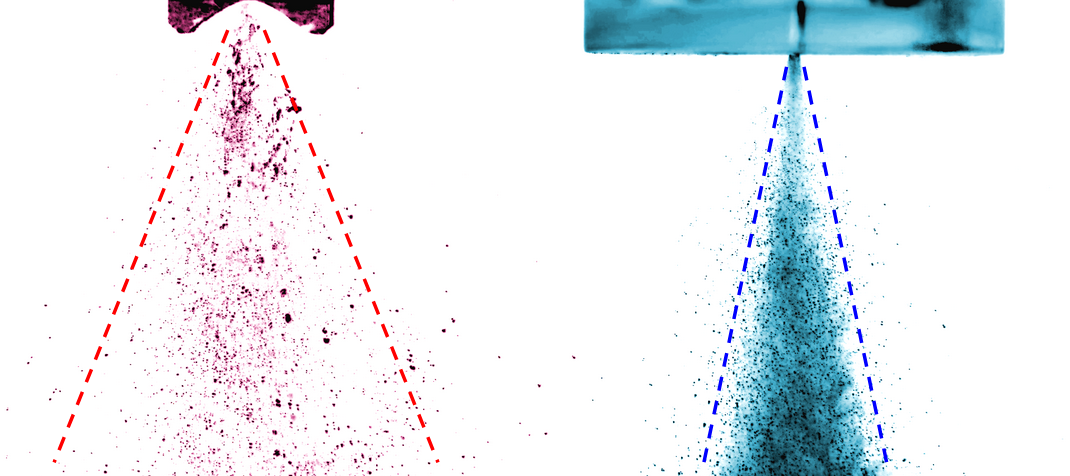

SFCL atomization research centers around counterflow atomization, a novel category of gas-assist internal mixing atomizer conceived at the University of Minnesota. In this design, gas is injected upstream against a resulting two-phase gas-liquid mixture exiting the atomizer. It is thought that the countercurrent velocity profile enhances turbulent gas-liquid mixing, ultimately aiding in liquid breakup. Initial work has demonstrated the potential to significantly improve on competing gas-assist efficiencies for 10-micron sprays, with cost reductions on the order of 50% possible for air-water sprays and even higher for viscous liquids such as propylene glycol. Observing bubble/droplet size and velocities through a variety of optical techniques, SFCL work seeks to characterize the two-phase flow in the internal mixing and orifice regions of counterflow atomization and quantify their effect on spray properties. This work also contributes to a broader understanding of countercurrent shear layers, a topic of considerable interest in single-phase gas literature but not yet explored in two-phase flows.